| 14)Impressed

Current And Anti-Fouling Systems

陰極防蝕系統

Impressed Current Cathodic Protection System (ICCP)

| Photo

View |

Details

& Description |

|

|

|

|

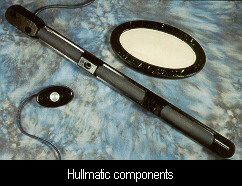

Hullmatic

Impressed Current Cathodic Protection System (ICCP)

The Wilson Taylor 'Hullmatic' ICCP system is designed to prevent

the external corrosion on underwater steel. Applications are

suited for ships, offshore rigs, semi submersible and other

marine structures.

ICCP systems were developed originally to protect the underwater

external hulls of large tankers and bulk carriers, which could

not be adequately protected by sacrificial anode systems. ICCP

systems are so successful that they are in common use on all

ranges of ships.

Each 'Hullmatic' ICCP system fundamentally comprises of four

main parts:-

1. Titanium anodes designed to last at least 20 years - either

linear surface mounted or recessed.

2. Zinc or sliver/silver chloride reference electrodes - either

surface or recessed.

3. Propeller shaft bonding slip ring and rudder stock cable

4. Automated control panel - rated from 100 amps to 800 amps

ANODES

All 'Hullmatic' anodes conduct D.C. protective current into

the seawater to maintain the hull potential at the correct level

to prevent corrosion occurring at areas when the paint has become

damaged. The anodes are constructed from titanium elements coated

with either platinum or mixed metal oxide. The elements are

encapsulated in a tough chlorine resistant resin carrier. Anodes

are available with capacity from 50 amps to 200 amps.

REFERENCE ELECTRODES

The reference electrodes are designed to give a stable reference

against which the hull to sea potential can be measured.

PROPELLER & RUDDER BONDING

To allow the protection for the propeller a high content silver

alloy band is attached around the shaft. Contact between the

shaft and hull is by way of silver graphite brushes.

Similarly, the rudder protection is ensured by the fitting of

a bonding cable, which is attached to the rudderstock and hull.

POWER SUPPLY UNITS

The 'Hullmatic' control unit is a thyristor-based unit with

a computer controller available with either analogue or digital

displays. The unit is in wide use today and recognised for its

reliability and robust quality in often harsh environments.

|

|

WILSON TAYLOR

海生物防蝕系統 MGPS

| Photo

View |

Details

& Description |

|

|

|

|

|

|

'Intakematic'

Marine Growth Anti-fouling Protection System

The Wilson Taylor Marine Growth Protection System (MGPS) is

designed to prevent marine growth from accumulating and reducing

corrosion within sea water pipes associated with seawater cooling

systems.

Marine growth is the result of settlement of the larvae and

subsequent growth of the shell type life such as Acorn Barnacle,

Gooseneck Barnacle etc. In extreme cases fouling can become

so serious as to completely obstruct pipes preventing the flow

of seawater through them. This can lead to complications with

cooling water flow and reduction of machinery efficiency, corrosion

and loss of speed - a serious situation especially when charters

demand a minimum speed.

The Wilson Taylor 'Intakematic' system is electrolytic in action

using copper and aluminium or iron anodes installed usually

in the sea chests which are fed by a low dc current from a constant

current control panel. The subsequent release of copper ions

is sufficient to deter settlement of larvae. The required level

of copper to prevent fouling is extremely small and measured

in micro grams per litre of seawater.

The 'Intakematic' system for the prevention of fouling has

the following advantages:-

• Simple Installation

• Operates automatically

• Minimum supervision required

• Complete protection against fouling

• Reduction in corrosion

• Minimal power requirement

Each Wilson Taylor System is designed to suit each vessel

and takes into account the following factors:-

1. Quantity of seawater to be treated (flow rate) in cubic meters

per hour.

2. Required life of anodes (usually dry docking interval for

sea chest mounted anodes).

3. Material of pipe works in the sea water system.

|

|